We Can Provide Extruder Line Including Masterbatch, LFT-G Lines,

LFT-D Lines

We can provide extruder line including masterbatch, LFT-G lines,

LFT-D lines, Filling and reinforcing modification, Special

engineering plastics.

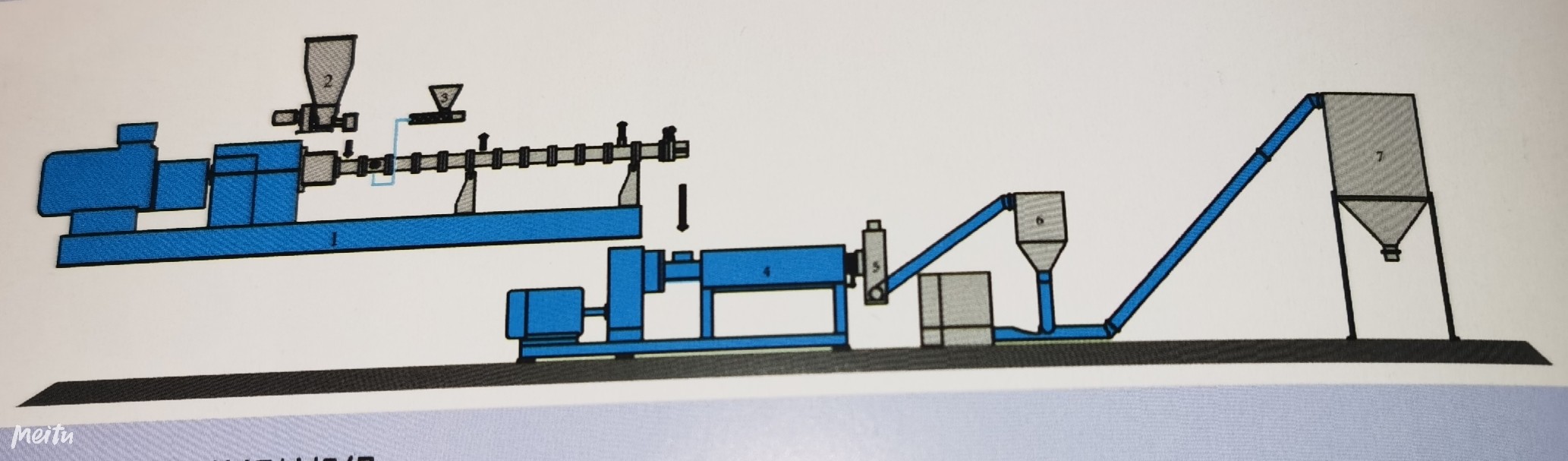

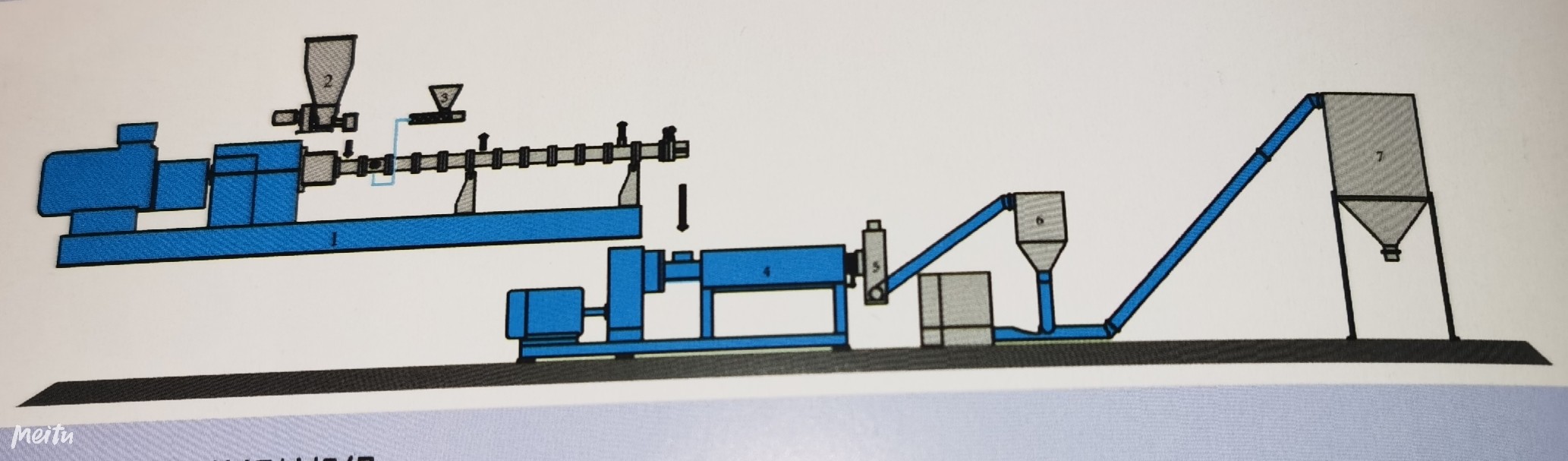

Water-cooling strand pelletizing extruder line for filling,

compounding, reinforcing polymer

Range of application: Reinforce modification, Filled modification,

Alloy

Typical matrial: PP, ABS, PET, PP; PC+ABS, PA+ABS; PP, PE,

EVA+CaCo3, Talc, Carbon black, ect.

Air-cooling pelletizing extruder line

Range of application: High temperature matrial processing.

Typical matrial: LCP, High temperature Nylon

Two stage air-cooling & die-face pelletizing extruder line

Range of application: Thermal sensitive polymer processing, Large

capacity exhaust release treatment

Typical matrial: PVC, PE, ect.

We are devoted to solve the core technical bottleneck of the power

transmission and torque distribution of twin screw extruder -- the

bearing capacity, durability and stability of the twin screw gear

box. Customized design and production of transmission system

according to different requirements of center distance, bearing

capacity coefficient and speedratio.

Our gear transmission technology is in step with the international

advanced level "bilateral symmetrical drive technology",

Thistechnology greatly improves the output capacity and torque of

the output shaft, while greatly reducing the stress on the output

shaft bearing. So the service life is greatly extended. Our gears

and shafts adout high-quality wear- resistant alloy, grinding the

hard tooth of gear surface with imported high precise machine tools

and detection technology. We adopt internationally recognized and

top-quality SKF and German INA bearing. With ADVS precise assembly

technology and foreign famous manufacturer equivalent level for

output torque, provides twin screw extruder manufacturers excellent

quality, reliable performance and high speed, high torque, high

performance gear boxes.